R & D TRUST&CHALLENGE

R & D Our company established a R&D institute on Nov. 1996 and do drastic investment and research in design technique, manufacturing technology and testing technique for a bright future of company. Reinforce technology competitiveness through standardization of design technology by acquisition of advanced technology and certification of ISO/IATF16949 through not only possession of a number of expert from each field and excellent facilities, accumulate various experience and self technology about automobile components like ENGINE, TRANSMISSION, etc. but also technical alliance with advanced foreign enterprise etc.

Institute of TechnologyResearch Result

-

Auto Tensioner

Acquired exclusive right of manufacturing and selling for Auto Tesioner of DOHC belt driving system from Tsubaki Motor Company -

P. C. V. VALVE

The largest maker of P.C.V Valve in Korea with ability to develop and has patents -

CAM SHAFT

4 wheels, 2 wheels and Marine Engine, we are able to process and measure the Cam Profiles -

Chain Tensioner

Not only for Timing belt system (Auto Tensioner), we are manufacturing Chain Tensioner for Chain Drive System.보

Institute of TechnologyCollaborative Technology

-

Imported production technology of hydraulic AUTO-TENSIONER from TSUBAKIMOTO CHAIN CO. Japan. (1994)

-

Import Japanese Tsubakimoto chain co. and design production technology of Chain tensioner Level, Guide, Sproket. (year 2001)

-

Imported production technology of hydraulic ASSEMBLY TYPE CAMSHAFT from MUSASHI SEIMITSU INDUSTRY CO. Japan. (2013)

Institute of TechnologyDesigned Technology

-

Built CAD SYSTEM LAN environment and performed independent design, production, and tested technology of the automobile part.

-

Design section status

CAD SYSTEM 8 PCS DESIGNING STAFF 5 2D CAD SYSTEM HELIX, AUTO CAD 3D CAD SYSTEM PRO-E(CREO), CATIA V5(R20) ANALYSIS PROGRAM ANSYS -

Design results

Design Product design

(approval drawing item)AUTO TENSIONER independently designed.

AUTO TENSIONER for SIRUS-II.

DELTA-ENG was designed and tested.

P.C.V.VALVE was designed and tested.

Processed design technology for the MX CAM SHAFT.

Designed technology of the DIESEL ENG CAM SHAFT.

DIESEL ENG CAM SHAFT design

OILJET ASSY design

CHAIN TENSIONER design

Machine design Self production and in the middle of operation of 100pcs of automation, sole use machine, test machine.

Institute of TechnologyCooperation Research

-

Period of research : 2003. 12.1 ~ 2006.8.31

-

Period of research : 2007.7.1 ~2008.2.29

- Project Name : PCV VALVE feedback verification flow program development -

Period of research : 2011.7.1 ~ 2012.4.30

- Project Name : Plastic type pcv valve design and verification flow program development -

Schematic diagram of

positive crankcase

ventilation

Geometry of X3 model

The Origin of displacement

Stress Contour of PCV

Velocity of PCV VALVE

Velocity of JET-OIL

Velocity of JET-OIL

Institute of TechnologyDesign Status

-

Inspection Equipment

Name of Equipment Standards Production Company Fleet 3 Dimensional measuring instrument 700(W)X1000(B)X500(H) CARL ZEISS 3 Instrument CAM PROFILE MODEL-1431 / 911NT ADCOLE 2 Roughness shape measuring instrument SEF-30D-R / DR 100*63 KOSAKA 2 Roundness measuring instrument EC1800 KOSAKA 1 Spring Tester KDYM10 신영 ENG 1 The projector PM350 MITUTOYO 1 Metallographic microscope EPIPHOT 200 NIKON 1 Rockwell Hardness Tester 500MRA other WILSON & MITUTOYO 3 Vickers Hardness Tester (MVH) MVK-G1 AKASHI 1 Brinell Hardness Tester 470*600*1000 DAE KYONG 1 Universal Material Tester (UTM) 20 TON DAE KYONG 1 Abrasive Cutter Ø255 KOREA TECH 2 Mountain Press 1"(25.4mm) BUEHLER Other 2 Polishing Machine 250 BUEHLER Other 2 2D Measuring Instrument 0-600mm TRIMOS 6 CMI(Plating thickness tester) 0-100M OXFORD 1 -

Test facility

Name of Equipment Standards Production Company Fleet Oil Jet / Check Valve Tester CHECK VALVE - 1 Open Pressure + Oil Jet / Check Valve Tester OIL JET ASS'Y - 1 P.C.V Valve Tester P.C.V VALVE - 6 Pulse Durability Tester P.C.V VALVE - 1 Diaphragm Durability Tester DIAPHRAGM - 1 Auto Tensioner Durability Tester AUTO-TENSIONER - 1 Auto Tensioner Durability Tester AUTO-TENSIONER - 1 Oil Chamber Durability Tester OIL CHAMBER - 2 Salt Spray Tester Plating(ALL ITEM)) - 1 -

Measurements and laboratory status

Name of Equipment Standards Precision measuring room area 50㎡ Calibration laboratory area 12㎡ Durability Laboratory area 60㎡

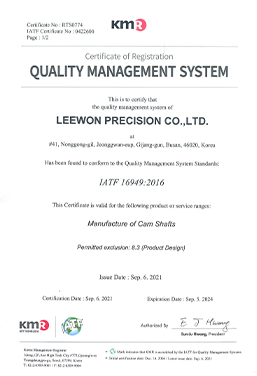

Institute of TechnologyCertificate

-

IATF 16949 Certification(KMR)

ISO14001 Certification(KMAR)

OHSAS 18001 Certification(KMAR)

IATF 16949 Certification(KMR)

OHSAS 18001